From earthquakes to micromachines

Predicting sliding motion at the nanometer scale

Samantha Jamison

Mar 2, 2017

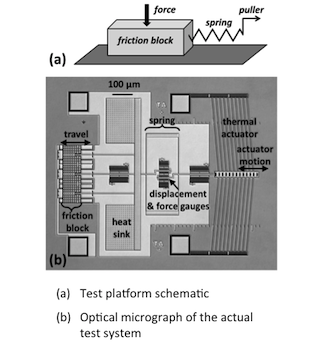

Friction controls earthquakes and is also important in car engines, wind turbine transmissions, and rolling processes to form metals. Due to the high surface-to-volume ratio of microelectromechanical systems (MEMS) devices, friction can dominate forces at the microscopic scale but its behavior is not well understood.

Carnegie Mellon University Ph.D. alumnus Sameer Shroff and Professor Maarten de Boer have been investigating this issue and published two companion papers detailing their research on micromachine friction. They applied a phenomenology known as the “rate-state friction” (RSF) framework, which has been shown to describe friction response at larger scales.

Source: Department of Mechanical Engineering

In the 1970s and 1980s, researchers developed RSF to describe their observations about earthquakes.

“Researchers trying to understand earthquakes noticed in experiments on rocks that static friction grows, or ages, with time, and that there is a memory length—the friction aging disappears if the relative motion between surfaces exceeds a certain length,” said de Boer, a professor of Mechanical Engineering.

“They also noticed that friction first decreases with velocity, then at higher velocity increases with velocity. The phenomenology helps explain many earthquake observations. One example is that it shows how stick-slip behavior can arise.”

This work helps put the theory of friction in micromachines on more sound footing.

Maarten P. de Boer, Professor, Mechanical Engineering, Carnegie Mellon University

The memory length is millimeters to micrometers for large objects, but Shroff and de Boer showed that the length is at the nanometer level in the micro machined interface.

“Based on Sameer’s measurements, we also made predictions of regimes in which steady sliding and in which stick slip should occur,” said de Boer. “We verified that these predictions were accurate in further experiments. This work helps put the theory of friction in micromachines on more sound footing. Forceful actuators that slide things around at the microscale need a predictive theory in order to be used in real applications. Such applications may include micro-optics, memory storage, and microrobots.”

References:

de Boer, M. P., & Shroff, S. S. (2016). Full assessment of micromachine friction within the rate–state framework: Experiments. Tribology Letters, 63(31). http://dx.doi.org/10.1007/s11249-016-0718-3

de Boer, M. P., & Shroff, S. S. (2016). Full assessment of micromachine friction within the rate-state framework: Theory and validation. Tribology Letters, 63(39). http://dx.doi.org/10.1007/s11249-016-0724-5