Leading the fuel cell charge

Shawn Litster earns recognition from the DOE for his leadership in developing clean, efficient, and cost-effective energy alternatives.

Marika Yang

Aug 2, 2019

With the current push for new environment-friendly solutions in the energy sector, fuel cells are alternatives to internal combustion engines. Fuel cells, which primarily use hydrogen as the fuel, are energy efficient, clean, and fuel flexible, with high energy density and no carbon emissions. One of major challenges in making fuel cells more available is the high cost of platinum, a part of the cell that works as a catalyst.

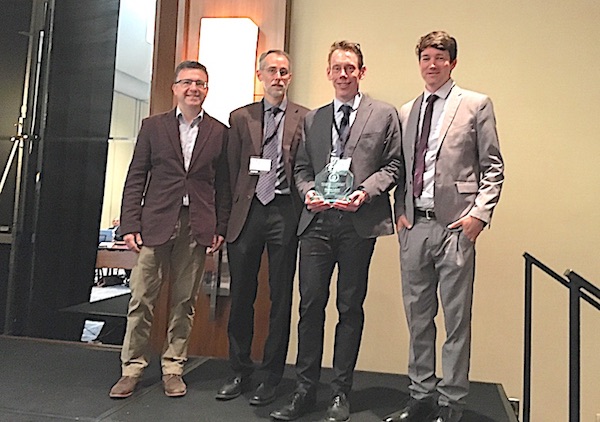

Shawn Litster, professor of mechanical engineering at Carnegie Mellon University, leads a team of researchers in academia and industry tackling this issue. He recently received a 2019 Annual Merit Review Award from the U.S. Department of Energy’s Hydrogen and Fuel Cell Program recognizing his leadership and work in fuel cell research and development.

Source: Shawn Litster

Litster and his team at Carnegie Mellon are working with materials developers at the State University of New York at Buffalo and companies 3M and Giner to develop fuel cells that do not need platinum. The group at SUNY Buffalo has developed a nanomaterial catalyst based on metal organic frameworks, made up of carbon, iron, and nitrogen. The project collaborates with 3M on polymers to bind electrodes in the fuel cell, while working with Giner’s facilities for scaling up production of these catalysts and electrodes.

“What we’re doing in the project here at CMU is looking at how you take this new nanomaterial and translate it into a high performance fuel cell that gives the performance and durability you need for applications like transportation,” says Litster.

The three-year project began in September 2017 and has passed the mid-way point. The team has achieved the highest platinum-free electrode performance reported at this time with a kinetic performance of 28.5 mA/cm2 at 0.90 V and 113 mA/cm2 at 0.8 V in H2/air. However, the difference between a platinum catalyst and the nanomaterial catalyst remains. The platinum-free fuel cell is performing well, but still at a lower rate that those with platinum, which leads to thicker electrodes and voltage and reactant concentration losses.

Developing a platinum-free fuel cell is a long-term enterprise. Today, the team’s fuel cell is approaching where the performance of a platinum catalyst was about 20 years ago. Research and development continue to work towards a point where fuel cells can be used for more vehicles, but Litster notes that they have applications beyond transportation.

“For example, one thing that’s really novel about them is that they don’t get poisoned by impurities in the air. So there have been demonstrations of these fuel cells for remote sensing where gas is being emitted from volcanoes, which would actually poison a normal fuel cell.”

With an integrated approach to optimization between Carnegie Mellon and its collaborators, the team continues to work on the project with U.S. Department of Energy’s Hydrogen and Fuel Cell Program. Their focus has turned to sustain platinum-free fuel cell performance for longer durations.

“We’re close to hitting our end of project goals in terms of the fuel cell performance at the beginning of its life,” says Litster. “Now it’s how long can we maintain an acceptable level of performance, and that’s actually where a lot of the challenges in the field still remain.”

Watch Shawn Litster in our latest Behind the Researcher video:

Media contact:

Lisa Kulick, lkulick@andrew.cmu.edu